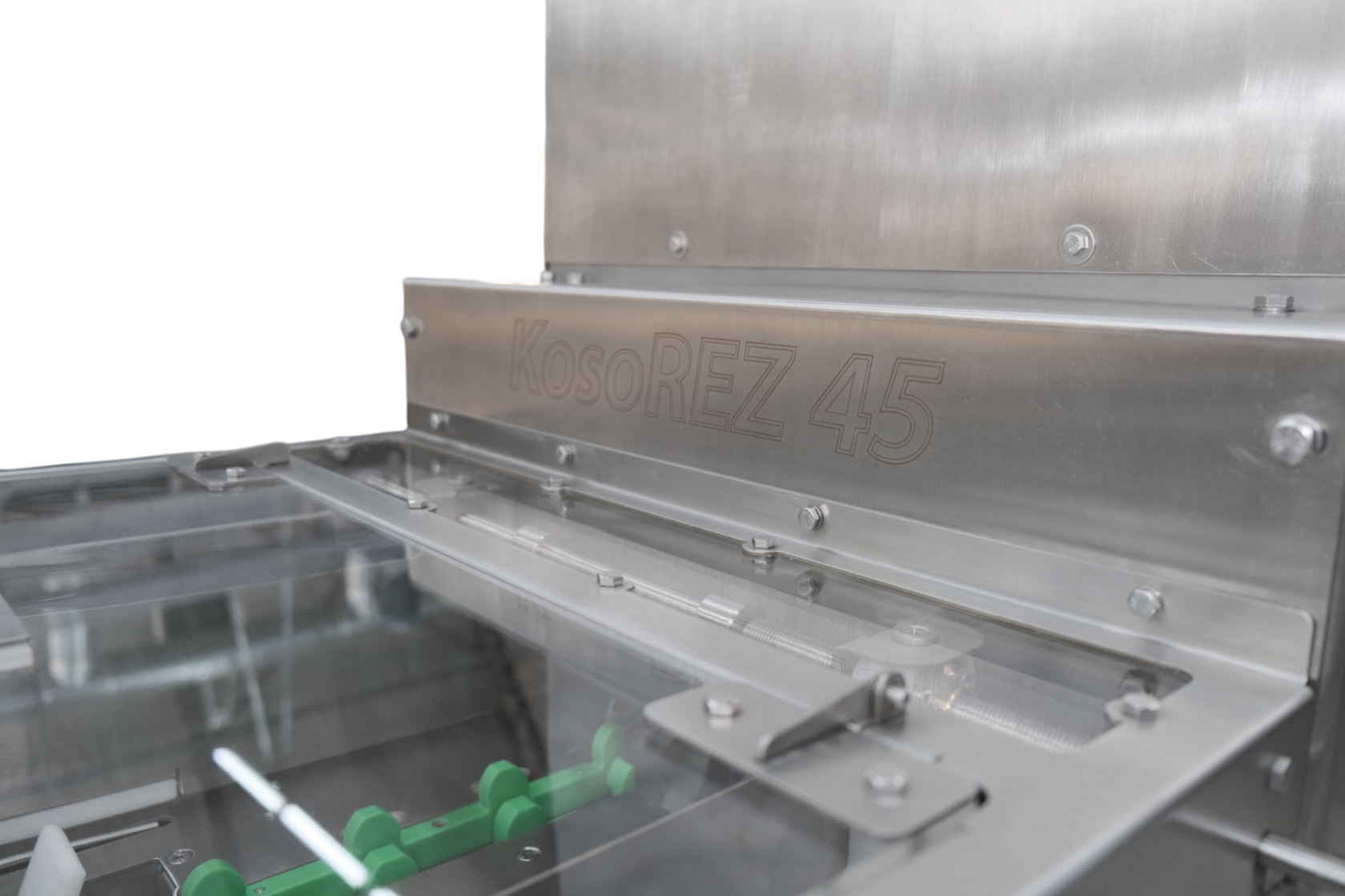

Automatic sausage loaf slicer

Cutting sausage loaves in half at a 45° angle: automation and precision in one unit.

As part of a large-scale automation project for sausage production and packaging, a sausage loaf divider – the 45° angle slicer – was installed. It performs cuts at angles from 45° to 70° as well as 90°. This solution accelerated product placement, enhanced shelf appeal, and ensured a high level of hygiene throughout the process.

As part of a large-scale automation project for sausage production and packaging, a sausage loaf divider – the 45° angle slicer – was installed. It performs cuts at angles from 45° to 70° as well as 90°. This solution accelerated product placement, enhanced shelf appeal, and ensured a high level of hygiene throughout the process.

What we have implemented:

– Installed an automatic 45° angle slicer – a machine that cuts sausage loaves and meat products in half at angles of 45°–70° and 90°

– Integrated it into a line with a singulator, labeler, and thermoformer

– Set up synchronization with the placement system for dual-chamber trays

– Ensured safe slicing of even clipped loaves without damaging the casing

– Integrated it into a line with a singulator, labeler, and thermoformer

– Set up synchronization with the placement system for dual-chamber trays

– Ensured safe slicing of even clipped loaves without damaging the casing

Benefits for the customer:

– Time savings on manual slicing and placement

– Improved hygiene (no hand contact)

– Enhanced product presentation on the shelf

– Increased line productivity by 15–20%

– Support for formats: cooked sausage, cooked-smoked products, loaves with and without clips

– Improved hygiene (no hand contact)

– Enhanced product presentation on the shelf

– Increased line productivity by 15–20%

– Support for formats: cooked sausage, cooked-smoked products, loaves with and without clips

Precision:

Cutting tolerance: ±1% of the loaf’s weight.

Product savings

The presence of a reject unit helps preserve large volumes of product.

It allows cutting one half of standard fixed weight from an underweight sausage loaf instead of discarding the entire piece.

The new generation of machines is ready for automatic placement of the halves into the packaging system.

It allows cutting one half of standard fixed weight from an underweight sausage loaf instead of discarding the entire piece.

The new generation of machines is ready for automatic placement of the halves into the packaging system.